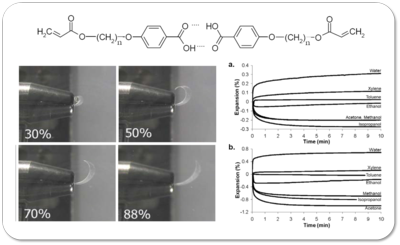

This side chain LCE has a unique mesogen structure that makes it responsive to chemical vapors. Unlike other LCE, the

mesogen of these materials contain hydrogen bonds to form the mesogens. The chemical structure of the hydrogen bonded

mesogen is shown at the top of the left hand image. When doped with either potassium or sodium ions,

these materials swell or contract with exposed to solvent vapor. The pictures at the bottom left show changes in the

structure of the LCE film when exposed to increasing relative humidity. As the

humidity increases and the film takes

up water vapor, it begins to expand along both axes, and uncurls. The bottom right plots change in film dimension

with exposure to different solvents for the long and short axis of the LCE film.

(ref. Self-Assembled Polymer Films for Controlled Agent-Driven Motion.

Nanometers (5)

, 2005

Thanks to Casper van Oosten of Prof. Broer's lab for his instruction on preparation of this material

This material is prepared in a cell coated with a poly-imide alignment layer. Nematic, smectic, splay and twisted nematic films may be prepared. The polymer network is formed by photo-crosslinking the material in the cell. After polymerization, the cell is opened and the material released from the surface.

- Chemical synthesis

- Mixture preparation

- Cell preparation & loading

- Release from cell

- Characterization

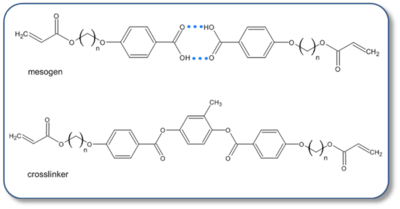

Chemical structure of the mesogen (top) and crosslinker (bottom). Individually,

the components do not adopt a LC phase. Hydrogen bonds, indicated as blue dotted lines between the individual components result in

a rod shaped LC mesogen similar to those found in other LCE. The number of carbons atoms in the flexible spacer

are 3, 5, & 6 carbon atoms.

Terminal acrylate groups are polymerized to form the LCE polymer

network.