LCE are a unique type of stimulus responsive material. The stimulus may be thermal, chemical, electronic, or photonic in nature, while the response arises from the coupling of the LC component and polymer component. Material response may be LC in nature, such as a change in optical properties, or rubber in nature, such as an elastic deformation. LCE materials may be prepared as thin films or fibers.

A response of particular interest is the large, reversible changes in shape. Depending on the material and preparation technique, the LCE may bend, contract, twist, or curl. Change in dimension may be very large, up to 400 to 500% contraction on the millisecond timescale. For perspective, a 400% contraction corresponds to a LCE film shrinking from 1 meter 6.25cm, making it an ideal candidate for artificial muscle applications. While not all LCE exhibit such a dramatic response, the ability of different types of LCE to respond to different types of stimuli provides a variety of material platforms that may be tailored for the desired potential for use as actuators, sensors, artificial muscles, plastic motors, drug delivery systems, tunable films for mirrorless lasing, novel seals and fasteners, optically responsive films and gels, tunable diffraction gratings, or smart material with reversible shape memory effects.Below, we highlight some potential applications of materials available from NLCMF.

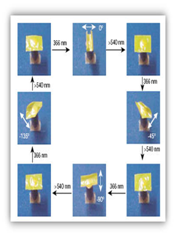

With the ability to reversibly expand and contract along one axis of the material along one axis, LCE are an ideal candidate for polymer based artificial muscle systems. The image to the right shows the reversible contraction-extension of an LCE heated / cooled above / cooled below some critical temperature, along the LC director axis (orientation the individual mesogen molecules) of the LCE film.

Source: Finkelmann group webpage; Liquid crystalline elastomers as artificial muscles H. Finkelmann, H. Wermter E-POLYMERS (13) 2001

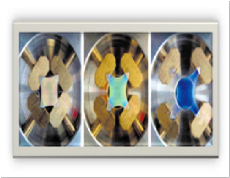

Cholesteric LCE are optical band gap materials used for mirrorless lasing applications. When these films are stretched, the distance (pitch)between cholesteric mesogens increases resulting in the change in color shown in the image above. When doped with an appropriate dye, a cholesteric LCE functions as a resonance cavity, providing mirrorless lasing from a film a few hundred micrometers thick.

Reference: Tunable Mirrorless Lasing in Cholesteric Liquid Crystalline Elastomers Advanced Materials (13) 2001

These materials efficiently convert light energy to mechanical energy through the incorporation of photosensitive azo-benzene derivatives into the LCE film. Already, this materials has been used to create a plastic motor that runs on light and artificial cilia, without material fatigue. Other potiential applications include light powered microactuators and micro-machines. Click here to see the motor in action