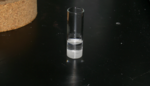

This procedure describes the preparation of spin-cast side chain LCE developed in Heino Finkelmann's lab. The total preparation for the material is approximately 48 hours. The image to the right shows an LCE film at the end of the spin casting process.

- balance

- weighing boat | paper

- glass vial | plastic > 5mL

- glass | plastic transfer pipette

- Teflon film (~20um thick)

- spin casting head

- heated centrifuge | spinning apparatus

- dry-ice | liquid nitrogen

- Tefzel tape (DuPont)

- 15 cm plastic | wood | metal rod for hanging LCE

This material is prepared using a heated centrifuge in a spin casting head. Before starting material preparation, pre-heat the spin casting head to 60 ~ 65oC.

The first step is preparation of the catalyst solution and reaction solution

- The platinum catalyst solution is prepared as a 1 to 2% weight/weight (w/w) solution in methylene chloride. Typically, this solution is prepared in quantities of 100 to 200uL in a brown vial and stored in the refrigerator.

- Example calculation for 1% (w/w)solution: Add 2 mg of the platinum catalyst to brown glass vial. Add methylene chloride drop wise until the total mass is 100 mg. This will be enough to prepare 5 batches of LCE

- Thoroughly clean the spin casting head and lid with toluene. Make sure there is no residual material from a previous run

- Cut the back support liner to the appropriate size. The size of the back support liner should be the same height as the wall of the spin casting head. The length of the strip should be the circumference of the spin casting head or up to 1cm longer.

- Wet the a kimwipe with toluene, and then wipe the back support liner with the kimwipe

- Carefully place the backsupport liner in the spin casting head. Once the film is seated against the walls of the spin casting head, check to make sure that the film is not too tall. To do this, run your finger along the top back wall of the spin casting head. If the support film is too tall, it will move.

- Place the lid on the spin casting head and preheat the head in the oven until it has reached the desired temperature For example, we let the spin casting head equilibrate for 2 hours when making a LCE at 65C