Silica gel chromatography is a common technique to purify a mixture of chemicals. For this technique, a glass column is filled with small silicate beads, known as the stationary phase. Next, the chemical to be purified is placed on top of the silica beads. Finally, a solvents are flushed through the column. As the solvent moves through the column, it carries along the chemical mixture placed at the top of the column, known as the mobile phase. As the solvent moves through the column, the components of the chemical mixture are carried along. The individual chemicals have different affinities for the silica gel, so some move faster and other more slowly, separating from each other in the process. The solvent is collected in fractions as it exits the column to obtain the desired product. A more detailed explanation of the process may be found here & here here & here

- balance

- weighing boat | paper

- glass vial | plastic > 5mL

- glass | plastic transfer pipette

- Teflon film (~20um thick)

- spin casting head

- heated centrifuge | spinning apparatus

- dry-ice | liquid nitrogen

- Tefzel tape (DuPont)

- 15 cm plastic | wood | metal rod for hanging LCE

This material is prepared using a heated centrifuge in a spin casting head. Before starting material preparation, pre-heat the spin casting head to 60 ~ 65oC.

The first step is preparation of the catalyst solution and reaction solution

- The platinum catalyst solution is prepared as a 1 to 2% weight/weight (w/w) solution in methylene chloride. Typically, this solution is prepared in quantities of 100 to 200uL in a brown vial and stored in the refrigerator.

- Example calculation for 1% (w/w)solution: Add 2 mg of the platinum catalyst to brown glass vial. Add methylene chloride drop wise until the total mass is 100 mg. This will be enough to prepare 5 batches of LCE

Column preparation

There are several strategies for loading a column with the silica mesh. Some prefer to add as slurry, while others prefer to add the silica gel as a dry powder. The method described here is for dry packing. We also use vacuum columns for faster separation, but the procedure described below will work for any type of column separation

- Fix the column in place with at 2 clamps, one near the bottom and one near the top.

- Place a funnel in the top of the column, and add ~1cm of sand. The sand should be level inside the column. Tap the side of the column to create a smooth surface. If using a non-fritted column, glass wool should first be placed in the bottom of the column.

- Pour in the silica gel between 1/2 and 2/3 full. Longer columns give better separation, but use more material. Columns with wider radii need less height and vice versa.

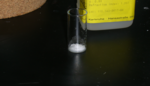

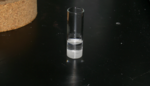

- Place another ~1cm of sand on top of the column. If sand is not available, glass beads may be used. When complete, the column should look like the picture to the right.

- Hit the column gently with a rubber hose to settle the silica gel and remove any air pockets air pockets in the gel reduce separation efficiency

Chemical mixture preparation

Several techniques can be used to load a sample on the column, we present the technique that we used at the facility.

- Place the reaction mixture in a round bottom flask, if not so already, and reduce to an oil on the rotovap.

- Add ~10 grams of dry silica gel to the reaction mixture, and dry on the rotovap until a fine powder. If the mixture does not dry down to a powder, you can add more silica gel free silica particles are visible in the flask.

- Using a funnel, pour the reaction mixture/silica gel one top of the sand (glass beads). If the gel/chemical mixture is not completely dry, is ok, but try to avoid to have any free flowing liquid in the flask.

Adding the mobile phase (solvent)

Choosing the ideal solvent mixture to elute the materials off of the column depends on the materials to be separated. It is suggested using the solvent sytems described in the synthesis procedures found on this website.

- Place a funnel in the top of the column, place a collection flask at the bottom of the column. If using a vacuum column, connect the vacuum line. Gather several flasks and label sequentially.

- Gently pour the mobile phase (solvent) into the column, until the column it is nearly full. Be careful not to disturb the surface of the column when pouring in the solvent.

- If using a vacuum column, turn on the vacuum to pull solvent through the column. If using a regular column, open the stopcock. Be extremely careful not to let the column run out of solution so that the silica gel (stationary phase) dries out.

- After a few mL of solvent comes off of the column, collect a droplet of the solvent using a capillary tube or a glass pull, and spot a TLC plate. Place the plate under a UV lamp to see when the materials start to come off of the column. Depending on the system, it may require several hundred mL of solvent before anything comes off of the column.

- After materials start coming off of the column, switch the collection flasks approximately every 100 mL. Spot the solvent on the TLC plate every minute or so to follow how the materials are coming off of the column. Run TLC on the collections to determine which flask (fraction) contains the product. The TLC plates used to monitor the reaction may be used for reference. When your product is obtained, you can stop collecting, but do not throw away the previously collected flasks.

- Run TLC on all flasks to determine which collection flasks contain the product. The product may be in more than one flask.

- Combine fractions that give the same TLC plates, and dry down in a rotovap.

Considerations

To maximize column efficiency, keep the sand and silica layers as even as possible. Do not let the column dry out, this will cause cracks to form, and can destroy the ability of the column to separate materials.