Checking the birefringence of the sample is a convenient method to check the alignment of LCE sample. Using linear polarizer films at placed at 90 degree angles is the simplest way to check birefringence. Or a microscope with cross polarized may be used. An excellent overview of birefringence in liquid crystals can be found here

- balance

- weighing boat | paper

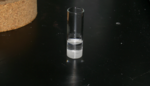

- glass vial | plastic > 5mL

- glass | plastic transfer pipette

- Teflon film (~20um thick)

- spin casting head

- heated centrifuge | spinning apparatus

- dry-ice | liquid nitrogen

- Tefzel tape (DuPont)

- 15 cm plastic | wood | metal rod for hanging LCE

This material is prepared using a heated centrifuge in a spin casting head. Before starting material preparation, pre-heat the spin casting head to 60 ~ 65oC.

The first step is preparation of the catalyst solution and reaction solution

- Place on of the polarizers on a light source such as a light box or in front of a light

- Place the LCE on top of the polarizer

- Position the second polarizer on top of the first polarizer and slowly rotate clockwise or counterclockwise

- For a well aligned film, the LCE sample should grow uniformly light and dark, as the polarizer is rotated and different polarizations of light either pass through the polarizer film or are blocked by the polarizer film.

- The images to the right show a well aligned sample and a polydomain sample. Note there are now changes in the appearance of the polydomain sample when the polarizer is rotated

- Before placing the sample on the microscope stage, rotate the one of the microscope's polarizers so the view field becomes completely dark.

- Place the sample on the stage

- Rotate the stage 90 degrees. A well aligned sample should uniformly turn light and dark

- Materials are transferred to the glass vial in the following order. If too much mesogen is added, it may be very carefully removed using a spatula. This is not the case for the crosslinker, as it comes in direct contact with the siloxane polymer. If too much of a crosslinker is added (> 2% mol) , use the spreadsheet to recalculate the amount of polymer required and carefully add additional polymer as needed

- Add thiophene free toluene. At room temperature, the materials will spontaneously dissolve in ~60 minutes.

The vial may be heated or gently vortexed to speed up the process. Make sure no materials is left on the side of the vial.

Allow the vial to return to near room temperature before adding the catalyst

- Record the actual amounts of material used in your lab notebook. Enter the values in the Excel spreadsheet to obtain a more precise estimate of crosslinker density.